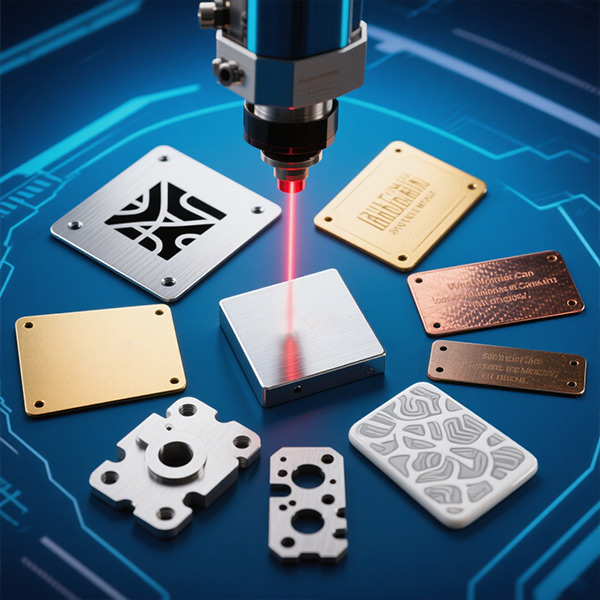

What Materials Can Fiber Laser Marking Machines Engrave?

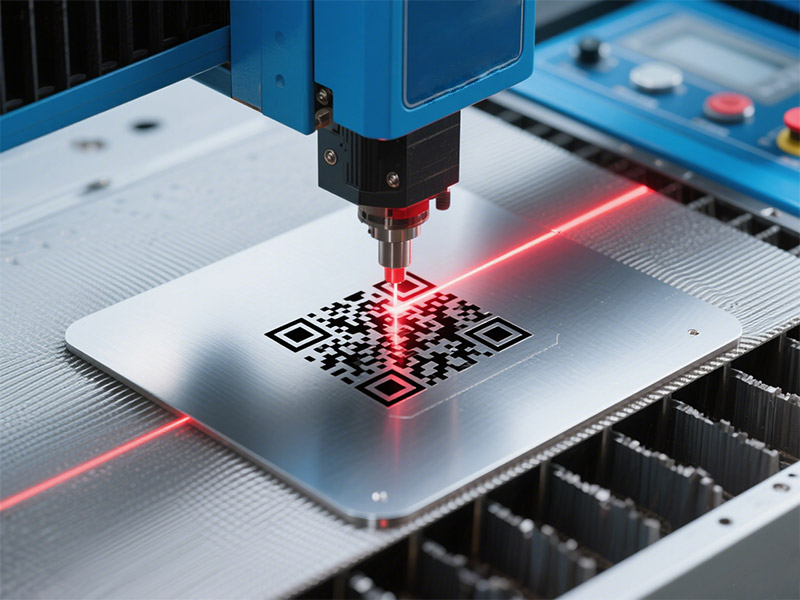

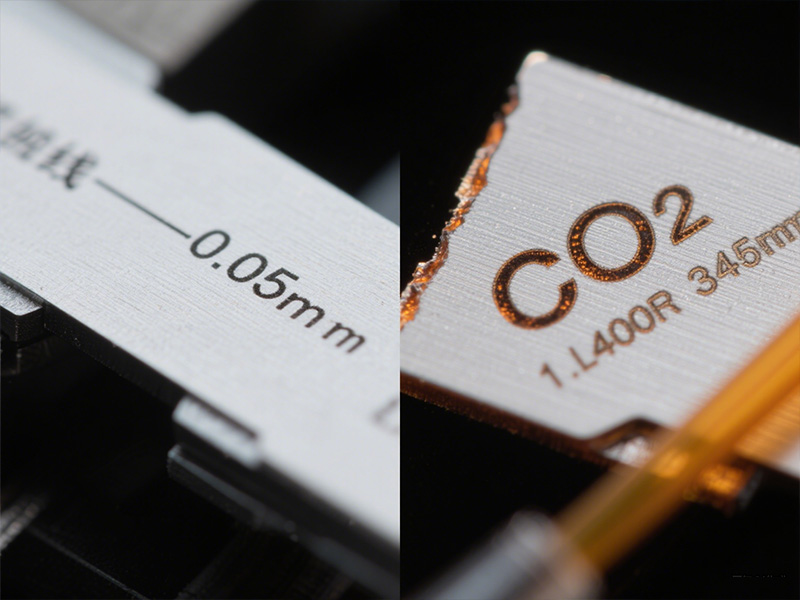

Fiber laser marking machines have become an indispensable tool in modern manufacturing. Known for their high precision, speed, and durability, fiber lasers are widely used to engrave or mark various materials, ranging from metals to select plastics. Unlike traditional marking methods, fiber lasers provide permanent, high-quality markings without the need for inks, chemicals, or physical contact with the material.